Heating Element Care & Maintenance

Whether you are making a 4″ seal or a 144″ seal, the nichrome heating element is the most important part of the heat sealing process! Heating elements should have a substantial life span when used under normal operating conditions. However, they will need to be replaced due to wear and tear over time.

Replacing the Heating Element

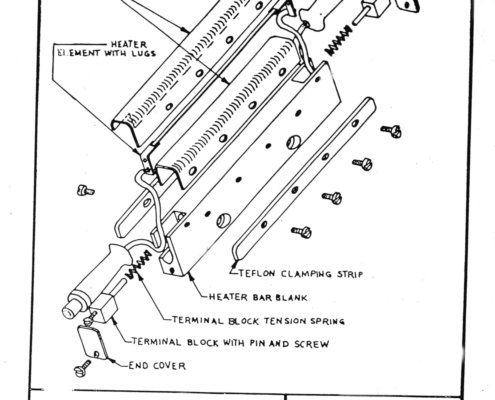

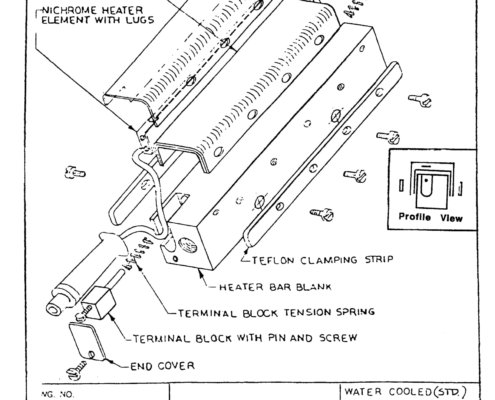

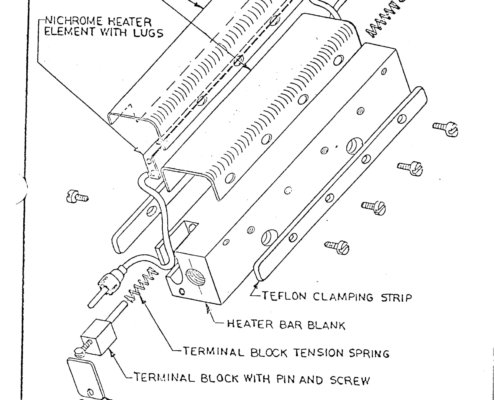

For heating elements with feeder lugs:

- Remove the end covers.

- Remove the top PTFE fabric cover that protects the element.

- Secure the spring-loaded terminal blocks into place with screws.

- Unfasten the screws that secure the feeder lugs to the terminal blocks. Remove the heating element from the terminal blocks.

- Remove and inspect the bottom PTFE fabric bottom cover that separates the element from the aluminum bar. If damaged, replace.

- Wipe a thin coating of silicone release agent on to the bottom cover.

- Unsolder the wire leads from the feeder lugs of the damaged element.

- Place the new element onto the heater bar and carefully bend the feeder lugs into place.

- Secure the heating element onto the terminal blocks with screws.

- Solder the wire leads onto the new heating element’s feeder lugs.

- Remove the screws that are holding the loaded terminal blocks and allow the heating element to become tensioned.

- Trim the bottom PTFE cover to fit between the two terminal blocks. Apply a thin coating of silicone release agent to the cover before centering it underneath the element.

- Apply a thin coating of silicone release agent on to the heating element.

- Replace the top PTFE fabric cover that protects the element.

- Put the end covers back into place.

*** If using PTFE Zone Tape, replace the bottom PTFE cover with a layer of PTFE tape. ***

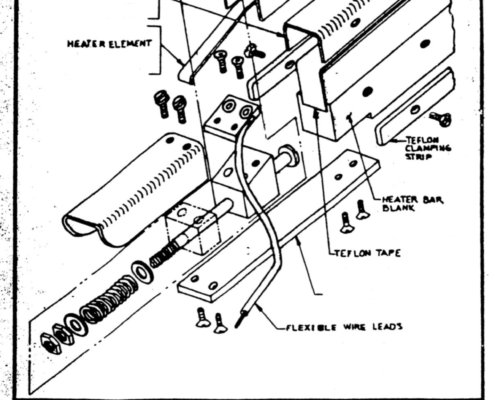

For heating elements with end assemblies:

- Unplug the wire leads from their sockets.

- Remove the end covers.

- Remove the top PTFE fabric cover that protects the element.

- Release the spring tension from the end assembly.

- Unfasten the screws that secure the heating element to the brass plates.

- Remove the heating element.

- Remove and inspect the bottom PTFE fabric cover that insulates the element from the aluminum bar. If damaged, replace.

- Inspect the PTFE tape that adheres to the aluminum heater bar. If damaged, replace.

- Attached the heating element in between the brass plates of one end assembly and fasten the screws so the heating element is held secure on one side.

- Place the heating element along the heater bar and pull the heating element through the other end assembly. With pliers, pull the heating element taut and lock the brass plate.

- Trim the bottom PTFE cover to fit between the two end assemblies. Apply a thin coating of silicone release agent to the cover before centering it underneath the element.

- Apply a thin coating of silicone release agent on to the heating element.

- Replace the top PTFE fabric cover that protects the element.

- Put the end covers back into place.

*** If using PTFE Zone Tape, replace the bottom PTFE covers with a second layer of PTFE tape. ***

Reasons for Heating Element Breakage

Typically heating elements should have a long lifespan when used properly.

Reasons for heating elements breaking:

- Opening the sealing jaws before the heat impulse cycle has ended will lead to the heating element becoming dangerously overheated.

- A foreign object becoming caught in between the sealing jaws will result in the heating element becoming kinked and permanent defects in the silicone rubber.

- Lack of insulation between the heating element and the aluminum heater bar will consequently result in a short circuit. This can be prevented by ensuring the PTFE covers are not worn out and they properly cover the aluminum.

- Defects in the silicone rubber will result in uneven pressure being applied across the heating element, thus resulting in hot spots. Eventually these hot spots will cause the element to weaken and break, and hot spots will burn your PTFE covers, product and silicone rubber.

- Omitting or having defective spring-loaded terminal blocks will result in heating element damage. The springs are designed to pull the heating element straight when the heating element expands during a heat cycle.